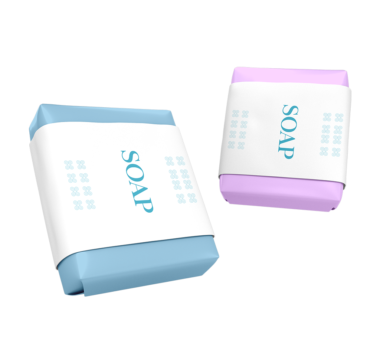

Are you looking for soap packaging paper that can not only help protect your soaps against environmental heat and moisture but also represent your brand in a favorable light? If yes, then you're at the right place. Packaging Bee creates some of the best soap packaging paper in the market.

Our high-quality raw material ensures that your soaps remain well protected during shipping and retail handling. Furthermore, you can decorate the paper using various printing techniques. By using our color models, your soap wrapping paper can have vibrant and brand-accurate shade. Furthermore, you can also use various add-ons and finishing coats to add personality to the soap packaging paper.

What are you waiting for? Get in touch with our team, and place your order today!