Make Your Customers Go WOW With Pharma Packaging

Pharma packaging refers to the materials and containers used to protect, store, transport, and dispense pharmaceutical products. These materials must meet strict requirements to ensure the safety, efficacy, and quality of the medication.

Pharmaceutical packaging includes a variety of materials such as bottles, tubes, blister packs, ampoules, sachets, and pre-filled syringes. These materials are designed to protect the medication from light, moisture, and air, and to prevent contamination and tampering.

Pharmaceutical packaging must also comply with regulatory requirements and industry standards to ensure the safety and quality of the medication. For example, packaging should be child-resistant, have clear labeling and instructions, and be tamper-evident.

So, what are you waiting for? Get your hands on our pharma boxes at Packaging Bee!

Manufacturing Materials For Pharma Packaging And Labelling

There are a variety of packaging materials that can use for custom pharma packaging design, depending on the specific requirements of the medication being packaged.

Some common options include:

-

Glass

Glass bottles are often used for liquid medications, as they are impermeable to air and moisture, which can help preserve the medication's efficacy. Furthermore, pharma packaging and labeling are also transparent, allowing for easy inspection of the contents.

-

Plastic

Plastic bottles or containers are commonly used for tablets or capsules, as they are lightweight and shatterproof. They can prepare from a variety of materials, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET).

-

Blister Packs

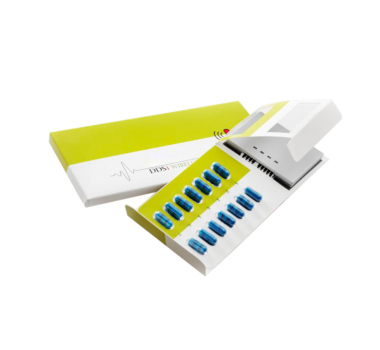

Blister packs are a type of pre-formed plastic packaging that holds individual doses of medication. In addition, they are commonly used for tablets and capsules and can design to be tamper-evident, child-resistant, or both.

-

Foil Pouches

Foil pouches are often used for medication that needs to protect from moisture or light, such as certain types of inhalers or patches. They are prepared from a combination of foil and plastic layers and can heat seal for additional protection.

-

Cardboard Boxes

Cardboard boxes are commonly used for packaging multiple doses of medication, such as in a monthly supply. They can print with custom graphics and branding and can include inserts or dividers to keep the medication organized.

-

High-Density Polyethylene (HDPE) Plastic

HDPE plastic is a popular choice for packaging pharmaceutical products due to its durability and resistance to moisture, chemicals, and UV rays. It is commonly used for bottles, jars, and tubes.

-

Aluminum

Aluminum is lightweight, durable, and resistant to moisture, light, and oxygen, making it an excellent choice for packaging pharmaceuticals. It is commonly used for blister packs, foil pouches, and tubes. When selecting packaging materials for custom pharma boxes, it's important to consider factors such as the medication's stability, shelf life, and dosing requirements, as well as any regulatory requirements or industry standards that may apply.

There are many pharma packaging companies, but the reliable one is PB!

Top Printing Methods For Custom Pharma Packaging

Several printing methods can use for custom pharma boxes, including:

-

Flexographic Printing

This is a common printing method used for high-volume printing of packaging materials. It involves printing on a flexible rubber or polymer plate, which is then used to transfer ink onto the substrate. Flexographic printing is often used for printing on corrugated boxes.

-

Digital Printing

Digital printing is a modern printing method that uses digital files to print directly onto the substrate. This method is ideal for printing small batches or for printing variable data, such as barcodes and serial numbers.

-

Offset Printing

Offset printing is a traditional printing method that uses metal plates to transfer ink onto the substrate. This method is ideal for printing high-quality images and text and is used for printing on paper-based materials.

-

Screen Printing

Screen printing is a versatile printing method that involves using a mesh screen to transfer ink onto the substrate. This method is often used for printing on irregularly shaped objects or for printing on materials such as plastics.

-

Gravure Printing

This is a high-quality printing method that uses a printing cylinder to transfer ink onto the box surface. It is suitable for printing large quantities of boxes and produces sharp and clear images.

When choosing a printing method for your custom pharma boxes, it's important to consider factors such as the desired print quality, the number of boxes needed, and the substrate material.

You may also want to consider whether you need to comply with any regulatory requirements for printing on pharmaceutical packaging. Get this type of printing from pharma packaging manufacturers in the market like us!

Coating Options For Custom Pharma Boxes

Several coating methods can use for custom pharma boxes, depending on the desired outcome and budget. Here are some common coating methods:

-

Film Coating

This is a process in which a thin layer of polymer is applied to the surface of the tablet or capsule. This coating can protect the contents of the tablet or capsule from the environment, as well as preserve the taste and odor of the contents.

-

UV Coating

This is a process in which a layer of UV-curable varnish is applied to the surface of the box. The coating is then cured using UV light, which hardens the varnish and creates a glossy finish.

-

Aqueous Coating

This is a process in which a water-base coating is applied to the surface of the box. This coating is typically used to protect the box from moisture and other environmental factors.

-

Varnish Coating

This is a process in which a layer of varnish is applied to the surface of the box. The varnish can be glossy or matte, depending on the desired effect.

-

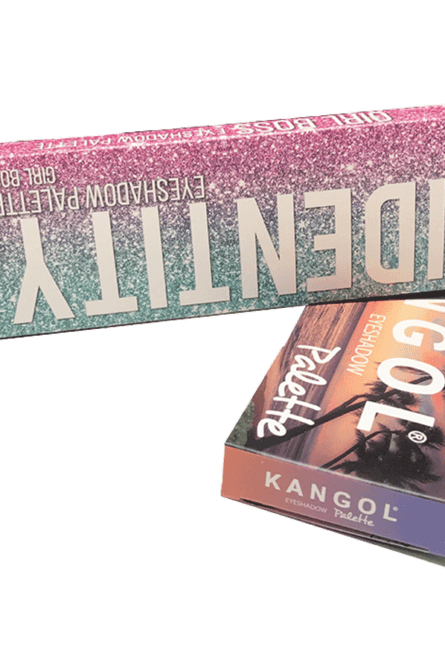

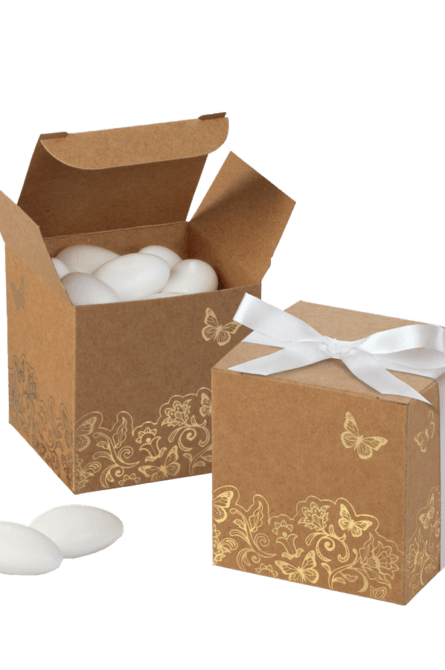

Hot Foil Stamping

This is a process in which a design is stamped onto the surface of the box using heat and pressure. This method can create a metallic or holographic effect and can use to add branding or other decorative elements to the box.

-

Embossing

This is a process in which a design is pressed into the surface of the box, creating a raised relief. This method can use to add texture and depth to the box and can combine with other coating methods for a more complex finish.

It is important to choose a coating method that is appropriate for the contents of the pharma box, as well as the ideal use and audience. Consulting with a packaging specialist can help ensure that the right coating method is selected for your custom pharma box.

Benefits Of Using Our Pharma Packaging Bottles

There are several benefits of using pharma packaging bottles, including:

-

Medicine Pill Box Improved Branding

Medicine pill box can design to feature your brand logo, colors, and graphics, which helps to improve brand recognition and awareness.

-

Enhanced Product Protection

Custom pharma packaging is designed to fit the specific dimensions of your products, which helps to protect them during transportation and storage. This reduces the risk of damage and ensures that your products arrive in good condition.

-

Increased Security

Custom pharma box design with security features, such as tamper-evident seals or anti-counterfeit measures, to protect against product tampering and illegal access.

-

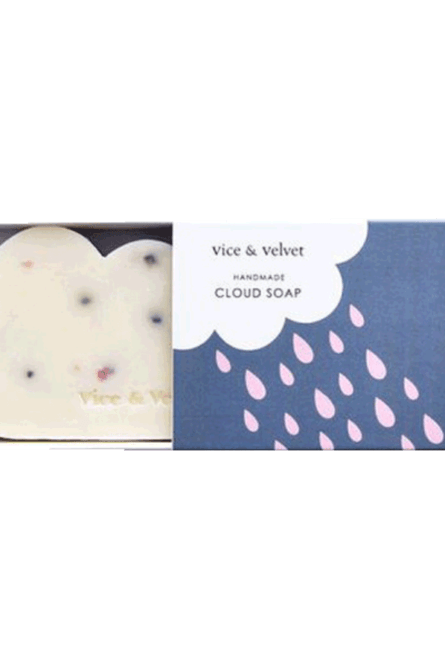

Better Customer Experience With Printed Folding Boxes For Pharma

Printed folding boxes for pharma can design to provide a better customer experience. For example, you can include clear instructions on how to use the product or incorporate user-friendly features such as easy-open tabs or tear strips.

-

Competitive Advantage With Custom Printed Pharma Boxes

By using custom printed pharma boxes, you can differentiate your products from those of your competitors. This can help you to gain a competitive advantage and increase sales.

-

Make Differentiation With Medicine Boxes

Custom medicine boxes can help pharmaceutical companies differentiate their products from competitors' products. Unique and eye-catching packaging can help grab the attention of potential customers and increase sales.

-

Sustainability With Medicine Drop Box

Medicine drop box can design with sustainable materials and practices in mind, reducing the environmental impact of packaging. This can help pharmaceutical companies meet their sustainability goals and appeal to environmentally conscious consumers.

Overall, custom pharma boxes can help to improve your brand image, protect your products, enhance customer experience, and increase sales.

Different Sizes Of Pharma Box

Custom pharma boxes can come in a variety of sizes to accommodate different types and sizes of pharmaceutical products. Here are some common sizes of custom pharma boxes:

- Small: Small custom pharma boxes are typically around 1-2 inches in width and length and around 0.5-1 inch in height. These boxes are often used for small items such as pills, capsules, and tablets.

- Medium: Medium custom pharma boxes are usually around 2-4 inches in width and length and around 1-2 inches in height. These boxes can use for larger quantities of pills or capsules, as well as for products such as creams and ointments.

- Large: Large custom pharma boxes can vary in size but are typically around 4-8 inches in width and length and around 2-4 inches in height. These boxes are used for larger quantities of medication or for products such as medical devices.

- Extra Large: Extra large custom pharma boxes are usually over 8 inches in width and length and over 4 inches in height. These boxes can use for large medical devices or for packaging multiple medications or medical supplies together.

Get From A Range Of Pharma Packaging Design Or Style

There are many different styles of custom pharma boxes available, and the style you choose will depend on your specific needs and preferences. Here are some popular styles:

-

Tuck Top Auto Bottom Box

This style of box has a tuck top lid that is easy to open and close, and an auto bottom that automatically forms when the box is assembled. It is a popular choice for pharmaceutical packaging as it is easy to use and provides excellent protection.

-

Reverse Tuck End Box

The reverse tuck end box has tuck ends that fold in opposite directions, with the top tucking in first and the bottom tucking in second. Furthermore, this style of custom packaging box is often used for smaller pharmaceutical products.

-

Seal End Box

The sealed end box has a flap that folds over and seals the box closed. It is a popular choice for pharmaceutical packaging as it provides a high level of protection and security.

-

Snap Lock Bottom Box

The snap lock bottom box has a bottom that snaps into place when the box is assembled. This style of box is often used for larger pharmaceutical products, as it provides extra strength and stability.

-

Pillow Box

The pillow box is a soft-sided box with curved edges that give it a pillow-like appearance. This style of box is often used for packaging small pharmaceutical products, such as pills or capsules.

-

Dispenser Box

The dispenser box is designed to dispense its contents one at a time. This style of box is often used for pharmaceutical goods that are meant to be taken daily or in small doses, such as vitamins or pain medication. Moreover, the best style for you will depend on your specific needs and the requirements of your product.

Book Your Orders Today

We are the US firm for packaging that people trust the most. We assist our clients in obtaining the premium packaging they want for their goods. Customers always get to choose the substance that we use to make their boxes. We provide our clients with personalized pharma packaging with their brand in any size and form, created to suit their preferences.

Compare to other businesses on the market, we at Packaging Bee provide our clients with the most affordable costs. Whether the order is little or large, we treat it similarly, are professional in the design, and provide free delivery to our clients.

In about 4 to 8 business days, we will deliver your purchase to your home!