What Are Packaging Inserts?

In order to improve the whole shopping experience and increase the value of the goods, packaging inserts are often included. Promotional brochures, instructional pamphlets, discount coupons, product samples, and thank-you cards are all examples of inserts. To build brand loyalty and increase repeat sales, package inserts should interact with and surprise consumers.

Improve consumer happiness and brand loyalty by including an insert with helpful product information, use advice, or instructions. They also function as a kind of advertising, highlighting related items, future sales, or customer loyalty programs. Businesses can strengthen their relationships with consumers. And make a greater impact with each unpacking experience by incorporating well-crafted package inserts that go beyond the product itself.

What To Look For When Buying Custom Packaging Inserts?

It's important to think about how your custom packaging inserts will improve the consumer experience and further your brand's mission while you're shopping for them. Try to find inserts that either add something unexpected to the product or provide useful information that complements the product itself. If you want your customers to believe that your brand is dedicated to quality, then you need to use excellent materials.

Choose adaptable features that let you include your brand's colors, fonts, and so on. Focus on using eco-friendly inserts to win over customers who care about the planet. Verify a snug and easy fit inside the box to avoid upsetting your clients.

If the inserts include crucial data, make sure they are in accordance with the law. It's important to think about what customers are saying while making choices.

Taking these into account can help you choose mailer inserts that will increase sales, and strengthen brand recognition. And provide an unforgettable unpacking experience.

Factors To Consider For Box Inserts

- Relevance to product

- Quality and durability

- The customizability of box inserts

- Eco-friendliness

- Space efficiency

- Legal compliance

Get A Wide Range Of Customization Options For Custom Box Inserts

Discover a wide variety of customization choices for your custom box inserts. Here at Packaging Bee, we're proud to provide a variety of options to meet your specific requirements. Inserts can be anything from instructional pamphlets to promotional materials to product samples to custom thank-you notes. And we can tailor each one to your brand's aesthetic and tone.

Inserts can customize to fit your goods and packaging by selecting from a wide range of sizes, shapes, and materials. We guarantee that your custom cardboard inserts will amaze your consumers and make a positive impression thanks to our dedication to quality and originality throughout the design process. Inserts that go above and beyond the norm can help you stand out in a crowded marketplace, so don't be afraid to use the power of customization to your advantage. The options are endless, and we have a keen staff ready to assist you in creating corrugated inserts that hit home with your demographic and inspire constant brand devotion.

Our Trendy Types Of Packaging Inserts

Various packaging inserts are;

-

- Paperboard inserts

- Cardboard inserts

- Corrugated inserts

- Rigid chipboard inserts

- Foam inserts

- Pulp packaging inserts

- Molded pulp

-

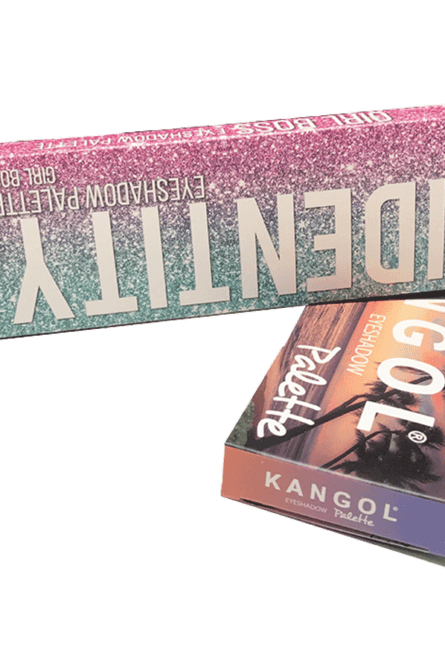

Paperboard Inserts

Lightweight and adaptable, paperboard inserts are used to store and show off a wide range of items. These inserts, which are manufactured from compressed layers of paper, are used to cushion and support fragile products inside the package. They can be quickly altered to accommodate a wide range of product sizes, making them perfect for cosmetics, electronics, and jewelry.

Paperboard inserts are often used by companies who want to display their products in the best light while still being environmentally responsible.

-

Cardboard Inserts

Strong and inexpensive, cardboard inserts are a great choice for shipping fragile items. These inserts are manufactured from stronger and thicker cardboard to prevent movement and damage during shipping. Glassware and other breakable objects are routinely sent and transported in them. In addition, die-cut or custom-shaped cardboard inserts provide a tight and secure fit for items, reducing the likelihood of damage during shipping.

-

Corrugated Inserts

In contrast to cardboard inserts, corrugated inserts provide much more protection. Corrugated paperboard, which has a fluted layer sandwiched between two flat sheets, is used to make them. This style is great for heavy or fragile things. Because of the additional padding and resistance to impact. Electronics, automobile components, and industrial machinery all benefit from the use of corrugated inserts for safe transport.

-

Rigid Chipboard Board Inserts

Inserts manufactured of rigid chipboard are ideal for protecting expensive machinery and tools. These inserts are prepared from strong and robust paperboard, so they won't flex and will provide your items with a solid base to rest on. When it comes to high-end products like watches, jewelry, and cosmetics, the presentation is just as important as the quality within.

-

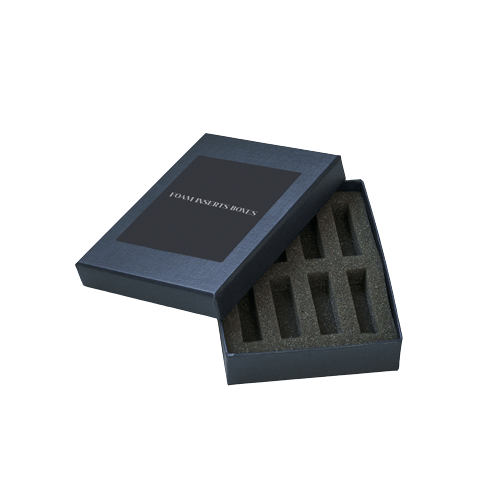

Foam Inserts

Foam inserts are a flexible and soft packing option that provides extra protection for fragile objects. They can tailor to the exact specifications of a product and are available in a range of densities. Because of the importance of shock absorption and impact resistance, custom foam packaging inserts are often used in electrical gadgets, medical equipment, and glassware.

-

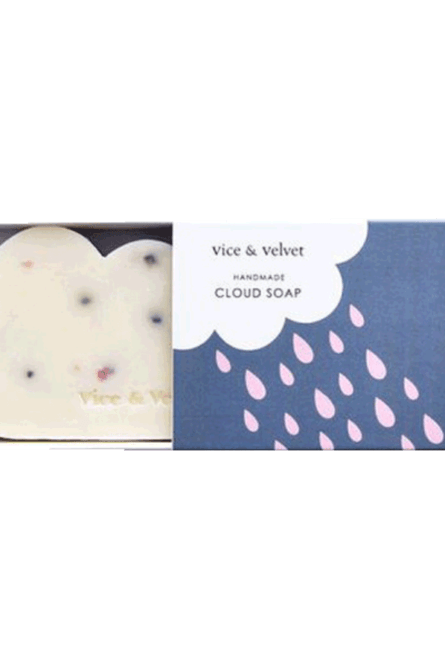

Pulp Packaging Inserts

Pulp package inserts, create from post-consumer recycled paper, are a green alternative. Because of their biodegradability and composability, they are a good option for eco-conscious companies. Cosmetics, food, and portable devices all benefit from the mild padding provided by pulp inserts.

-

Molded Pulp Inserts

Inserts prepared from molded pulp are manufactured by molding a pulp material into the desired shape. They provide superb security for fragile or oddly shaped products in transportation. Electronics, automobiles, and home appliances often have molded pulp inserts in their packaging. There are many different kinds of package inserts available, and each one serves a certain purpose and meets specific needs. Selecting the best insert for your items will guarantee they get to clients undamaged, look great, and are ready to be used.

What Are Our Packaging Inserts For Boxes Made Of?

Our packaging inserts for boxes are prepared from a wide variety of high-quality and eco-friendly materials that have been meticulously selected to provide the highest levels of protection, presentation, and longevity.

Because we care about the planet, we give preference to resources that help us do our part to lessen our impact. Our inserts are typically fabricated from the following:

-

Paperboard For Gift Box Inserts

Paperboard gift box inserts are a great way to protect fragile items during shipping since they are inexpensive and easy to ship.

Cosmetics, electronics, and jewelry are just some of the little things that benefit from this aesthetically pleasing and environmentally friendly packaging option.

-

Cardboard Custom Boxes With Inserts

Custom boxes with inserts manufacture from cardboard are sturdy; they are used to keep things in place during shipping. In addition, you'll often see them use to transport delicate porcelain, glassware, and other such things.

-

Corrugated Cardboard

The fluted form of corrugated inserts makes them very cushioned and impact resistant, adding an additional layer of defense. They're often used for transporting electronics and industrial machinery since they're suitable for transporting large or fragile items.

-

Other Substantial Materials

We also look into alternative eco-friendly choices including pulp packaging inserts, hard chipboard, and recyclable plastics to cater to our clients' varying preferences.

Custom Inserts For Boxes Featuring Unique Printing And Other Designs

Custom inserts for boxes can be printed in a variety of ways.

-

Offset Printing For Box Inserts For Shipping

Offset printing, a common and flexible custom printing method, is use to print designs on box inserts for shipping in high quality and with fine detail. To print on the insert, ink is transferred from a metal plate to a rubber blanket. Offset printing is great for intricate designs and colorful artwork due to its accurate color reproduction, sharp images, and consistent results.

This printing technique is ideal for mass production because it minimizes expenses without sacrificing results. The versatility of offset printing means that different inks and finishes, like matte or gloss coatings, can use to great effect, improving both the visual appeal of the custom inserts and the overall presentation of the packaging.

-

Digital Printing For Custom Product Inserts

When it comes to producing unique inserts in smaller batches, nothing beats the efficiency and adaptability of digital printing. Digital printing eliminates the need for printing plates by printing the design directly onto the insert.

For personalized custom product inserts, digital printing is the best option due to its on-demand printing, fast turnaround times, and easy customization. With this method, you can be sure that even the finest details and most complex artwork will reproduce faithfully. Brands that want to print unique inserts with variable data or designs can do so affordably through digital printing.

-

Screen Printing For Product Packaging Inserts

Using a stencil and a mesh screen, screen printing is a flexible custom printing technology that can use to transfer ink to the surface of the product packaging inserts. It works well for printing colorful, eye-catching graphics on a wide range of substrates, from foam board to paperboard. The ink coverage and graphics quality of screen printing are superior to other printing methods. This technique is ideal for printing on non-standard insert shapes or for adding embellishments like raised textures or metallic inks to the final product.

Screen printing is ideal for printing on custom inserts for use in harsh or heavy-duty applications because of the print's durability and longevity.

-

Foil Stamping for Package Insert Design

Adding metallic or holographic foils using foil stamping is a classy and sophisticated custom printing technique. Using heat and pressure, the foil is transferred to the insert's surface, where it creates a stunning and sumptuous look. Foil stamping gives the personalized inserts a luxurious look and feel, helping them stand out on store shelves and generating a lasting impact on buyers.

This strategy is often used by high-end manufacturers and luxury labels to improve the visual appeal of their package insert design. Foil stamping's versatility in foil color and finish allows for individual expression and adaptation to the needs of the brand's look.

Artwork Preparation Guide For Retail Packaging Inserts

For your retail packaging inserts to make an everlasting impact on your clients, you need to ensure they have eye-catching artwork. If you want your artwork preparation process to go smoothly and efficiently, follow these detailed instructions. To name a few are;

- Understand Insert Specifications: Learn the exact measurements, contours, and arrangement of the product insert template in the package. Your artwork must be the correct size and shape to fit into the insert.

- High-Resolution Graphics: If you want crisp, clear prints, you need high-resolution photos and graphics. Choose vector images instead of bitmaps for logos and drawings so they look great at any size.

- Color Mode: If you want true colors printed from your artwork, you should choose the CMYK color option. If you want your printed product to look well, it's best to stay away from RGB or spot colors.

- Bleed and Safe Zone: Make sure there are no white margins after trimming by extending your artwork over the trim line to create a bleed area. Don't risk having text or images chopped off in the printing process by keeping them outside of the safe zone.

- Font Selection: Make sure the typefaces you choose in your designs can be easily read and printed. To prevent problems while printing due to fonts, embed the fonts or transform the text to outlines.

- Design Balance: Maintain an attractive design while ensuring a well-balanced layout that draws attention to key details. Don't stuff the insert with too much information or too many images.

- Proofreading: Make sure there are no typos, spelling faults, or grammatical flaws in anything you’ve written. Before submitting the finished artwork, make sure it has been thoroughly proofread.

- Mockup and Prototyping: To see how the final product will look and make any required revisions before manufacturing, it is recommended to create a digital mockup or physical prototype of the insert.

- File Format: PDF or Adobe Illustrator (.ai) files, with integrated fonts and associated pictures, are print-ready formats.

- Printing Compatibility: You should check with your packaging service to see whether the artwork you've prepared will fit with their printing specs.

- Test Printing: Before starting a large-scale print run, it's a good idea to run a test print to make sure the colors, size, and layout are all as expected.

You can save time and effort throughout the artwork creation process and improve the readability and aesthetic attractiveness of your package inserts by adhering to these standards.

A customer's unpacking experience will be more pleasant and memorable if the accompanying artwork has been carefully crafted.

Choose From Our Different Size Options

The following size options are;

- Small Size: Perfect for compact products and limited insert space.

- Medium Size: Versatile and commonly used for a wide range of products.

- Large Size: Ideal for bigger items or inserts requiring more content.

- Custom Size: Tailor to fit specific product dimensions and packaging requirements.

- Standard Size: Conforms to industry-standard dimensions for convenience and compatibility.

- Mini Size: Smaller than small size, suitable for tiny or delicate items.

- Oversized Size: Larger than the standard size, offering ample space for creative designs and information.

- Square Size: Square-shaped inserts for a unique and modern presentation.

- Rectangular Size: Classic rectangular inserts, well-suited for various product shapes.

Select the size that works best with your product and package layout to get the greatest possible fit and display from your packaging inserts.

Add-Ons For Packaging Inserts

Add these fascinating add-ons to your package inserts to boost their attractiveness and usefulness:

- Die-Cutting: Make creative and eye-catching inserts in whatever form you choose to match your items' packaging.

- Foil Stamping: The visual impact of your inserts will be greatly improved by the use of metallic or holographic foils, which provide a sense of luxury and elegance.

- Spot UV Coating: Create a remarkable contrast between glossy and matte by emphasizing certain parts of your artwork with a glossy and raised appearance.

- Embossing: Raise designs or logos on your inserts to provide a more elegant display.

- Debossing: Adding debossing, which is like embossing but creates a sunken look, to your inserts is a simple way to make a big impression.

- Foldable Inserts: Foldable inserts that unfold to reveal more text or display numerous goods are a great way to make the most of limited real estate.

- Window Cutout: Use window cutouts to display your goods or provide quick access to important information without having to open the insert.

- Perforation: To attract attention and give value beyond the box, consider including tear-off pieces or interactive aspects.

- QR Codes or Augmented Reality: Add QR codes or augmented reality elements to direct users to digital material or special deals.

- Personalization: Personalizing each insert with a name or message will make the experience more unique and memorable for your clients.

- Fold-Out Brochures: Include fold-out pamphlets within the insert to enlighten clients about your company and its offerings.

These add-ons let you make package inserts that really stand out, get people talking about your goods, and make an impact that lasts. Pick the extras that complement the image and goals of your brand's packaging to give your inserts a creative and practical boost.

Pick Us Up Today!

Put your trust in us for all of your packaging requirements right now. We at Packaging Bee have a history of success, making us a trustworthy resource for innovative packaging strategies.

Utilize originality, superiority, and exemplary service as we strive to go above and beyond your expectations and improve the reputation of your brand. Our flexible ordering choices, commitment to sustainability, and prompt shipping will get your items noticed. Come be a part of our happy customer family and see how packaging inserts can change your life.

The choice you make now can determine the future of your brand. Pick us now and we'll be the engine that propels your packaging to the top!