Buy Our Mylar Bags At A Wholesale Price

Let’s know what is a mylar bag. Looking to purchase high-quality mylar bags at a wholesale price? Look no further! We offer a wide range of premium custom bags that are perfect for your packaging needs. Our bags are prepared from top-grade materials to ensure durability and protection for your products. With our wholesale pricing, you can save big while still receiving top-notch quality.

Whether you're in the food, beauty, or pharmaceutical industry, our mylar packaging bags are designed to meet your specific requirements.

Don't miss out on this opportunity to enhance your packaging and impress your customers. Shop with us today and get the best value for your money with our custom mylar bags.

Mylar Bags For Food Storage- Material Options

When it comes to bags, there are several material options available, each with its own unique characteristics and benefits. Here are some common-use materials for custom bags:

-

Polyethylene (PE) Bags

These mylar bags for food storage are prepared from a type of plastic called polyethylene. They are known for their durability, flexibility, and moisture resistance. PE custom bags are commonly used for storing dry goods, snacks, and lightweight items.

-

Polypropylene (PP) Bags

Polypropylene mylar bags near me offer excellent clarity, making them ideal for showcasing products. They have high tensile strength and are resistant to punctures and tears. PP mylar packaging bags are often used for packaging products like candies, nuts, and dried fruits.

-

Aluminum Foil Bags

These bags are created with a layer of aluminum foil laminate to other materials such as plastic or paper. Aluminum foil provides exceptional barrier properties, including resistance to moisture, oxygen, and light. These bags are commonly used for packaging perishable items, pharmaceuticals, and sensitive electronics.

-

Metalized Bags

Metalized bags are created by depositing a thin layer of metal, usually aluminum, onto a polyester film. They offer similar barrier properties to aluminum foil bags but with a lighter weight. Metalize mylar bags wholesale is widely used for packaging coffee, tea, spices, and other products that require protection from moisture and UV light.

-

Nylon Bags

Nylon mylar packaging bags are known for their high puncture resistance and oxygen barrier properties. They are commonly used for packaging perishable foods, such as meat and cheese, as well as for vacuum-seal storage.

-

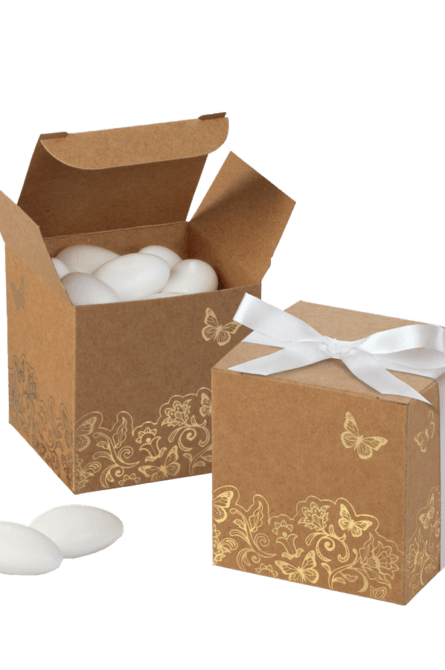

Kraft Paper Bags

These bags combine the strength and durability of kraft paper with the barrier properties of mylar. They are eco-friendly and provide a rustic appearance, making them popular for packaging natural and organic products. When choosing the material for your smell proof mylar bags, consider the specific requirements of your products, such as the need for moisture resistance, oxygen protection, or visibility. Selecting the right material will ensure that your products stay fresh, protected, and visually appealing.

Look At Our Printing Methods For Bulk Mylar Bags

We offer a variety of detailed printing methods for bags to help you create eye-catching and customized packaging for your products. Here are some of the printing options available:

-

Flexographic Printing

Flexographic printing is a popular method for printing on bulk mylar bags. It involves transferring ink onto the bags using flexible rubber or photopolymer plates.

This printing allows for high-speed production and can accommodate a wide range of designs, including intricate graphics and fine details.

-

Digital Mylar Bags Printing

Digital printing is a versatile and efficient printing method for customized mylar bags. It involves directly printing the desired design onto the bags using digital technology.

This mylar bags printing offers excellent color accuracy, quick turnaround times, and the ability to print variable data and personalize designs. It is suitable for small to medium-size print runs and offers flexibility in design choices.

-

Gravure Printing

Gravure printing, also known as rotogravure printing, is a high-quality printing method commonly used for custom mylar bags wholesale. It involves etching the design onto a cylinder, which is then inked and transferred onto the bags. This printing offers consistent results, vibrant colors, and the ability to reproduce intricate artwork with excellent detail.

-

Lithographic Printing

Lithographic printing, or offset printing, is another option for printing on mylar bag design. It involves transferring ink from a printing plate to a rubber blanket and then onto the bags. In addition, lithographic printing offers high-quality results, sharp images, and consistent color reproduction. Moreover, it is well-suit for large print runs and is ideal for complex designs and illustrations.

-

Screen Printing

Screen printing is a versatile printing method that can use for custom mylar bags wholesale. It involves pushing ink through a mesh screen onto the bags, creating a layer and vibrant print. This printing allows for precise color control, special effects such as metallic or fluorescent inks, and the ability to print on various bag sizes and shapes.

-

Hot Stamping For Packaging Mylar Bags

Hot stamping is a popular method for adding metallic or foil accents to packaging mylar bags. It involves using heat and pressure to transfer a metallic foil or colored film onto the bags, creating a shiny and decorative effect. Hot stamping is often used for logos, brand names, or embellishments that add a touch of elegance and luxury to the packaging.

When choosing a printing method for your mylar bag template, consider factors such as the complexity of your design, desire print quality, budget, and production volume. Our printing experts at Packaging Bee can guide you in selecting the most suitable printing method to bring your design to life and create visually stunning mylar bags for sale for your products.

Lamination Options For Our Best Mylar Bags

When it comes to lamination options for the best mylar bags, there are several choices available to enhance the functionality and appearance of your packaging.

Here are some commonly used lamination options for custom packaging mylar bags:

-

Clear Lamination

Clear lamination adds a thin layer of transparent film to the wholesale mylar bags, protecting against moisture, dirt, and abrasion while maintaining the visibility of the product inside. This option is ideal for showcasing the contents of the bag while ensuring its integrity.

This lamination not only adds a glossy shine to the bag but also protects it from moisture, dirt, and damage. This option allows the contents of the bag to be visible, making it ideal for showcasing products with vibrant colors or intricate designs.

Clear lamination is a popular choice when you want to combine visibility, protection, and a sleek, professional look for your mylar bags made in USA.

-

Matte Lamination

Matte lamination gives the mylar bag a non-glossy, satin-like finish. It adds a layer of protection while reducing glare and providing a smooth, elegant appearance. Matte lamination is often chosen for products that aim for a classy and premium look.

This option is ideal for achieving a sophisticated and understated aesthetic, giving your custom shaped mylar bags a premium and tactile feel. Matte lamination not only adds a layer of protection against scratches, moisture, and general wear and tear but also provides a pleasant tactile experience for customers.

It is a popular choice for packaging products that aim for a classy and modern presentation, allowing your brand and design to stand out uniquely.

-

Glossy Lamination

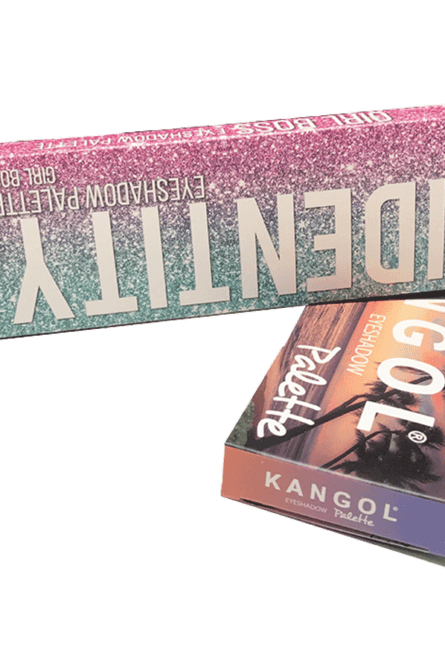

Glossy lamination adds a shiny, reflective coating to the mylar bag, enhancing its visual appeal and creating a vibrant and eye-catching effect. It provides an elegant and professional look, making it suitable for products that want to stand out on the shelves.

This option is perfect for creating a sleek and professional look, especially for products that want to exude a sense of luxury or attract attention on store shelves. Glossy lamination not only enhances the bag's aesthetics but also provides a protective barrier against moisture, dirt, and general wear and tear, ensuring that your products remain in pristine condition. It is a popular choice for various industries, including cosmetics, food, and retail, where a glossy and vibrant appearance is desired to create a lasting impression on customers.

-

Metalized Lamination

Metalized lamination involves applying a thin layer of metallic film to the mylar bag. It offers an attractive and metallic appearance, providing a unique and futuristic look.

This lamination option is often chosen for products that want to create a distinctive and attention-grabbing packaging design. Furthermore, the reflective nature of the metalized lamination adds a touch of sophistication and elegance to the bag.

The shimmering effect creates a visually captivating appearance, making the bag stand out on store shelves and attracting attention. This option is particularly popular in industries such as food, beverage, and cosmetics, where a premium and high-end presentation is desired.

-

Soft-Touch Lamination

Soft-touch lamination gives the mylar bag a velvety and smooth texture, providing a luxurious tactile experience for customers.

It adds a premium feel to the packaging and is often selected for high-end products or brands that want to convey a sense of elegance and sophistication.

These lamination options not only offer additional protection to your bags but also contribute to the overall aesthetic appeal and brand image. Depending on your specific requirements and the desired look and feel of your packaging, you can select the appropriate lamination option that best complements your product and enhances its shelf presence.

Common Queries To Know About Custom Shaped Mylar Bags

There are some queries that most customers want to know. Take a look below!

-

What Is The Best Place To Buy Mylar Bags

When it comes to buying bags, finding the best place to make your purchase is essential to ensure product quality, variety, and customer satisfaction. Get your bags now at Packaging Bee- the top printing or packaging company online.

-

Where To Buy Mylar Bags

The only answer to this question is Packaging Bee!

-

What Are Mylar Bags Made Of?

Mylar bags are typically prepared from a material called BoPET, which stands for biaxially-oriented polyethylene terephthalate. BoPET is a type of polyester film that is known for its exceptional strength, durability, and barrier properties.

-

What Are Mylar Bags Use For?

Mylar bags are commonly used in the food industry to package snacks, dried fruits, coffee, tea, spices, and other perishable goods, as they help maintain freshness and extend shelf life.

-

Are Mylar Bags Recyclable?

Yes, our mylar bags are 100% recyclable!

-

Are Mylar Bags Reusable?

Yes, Mylar bags can be reusable depending on their condition and the nature of the contents they have been used to store.

-

How To Seal Mylar Bags?

To seal Mylar bags, you will need a heat sealer. Here are the steps:

- Fill the bag with your desired contents.

- Leave enough space at the top of the bag to seal it properly.

- Place the open end of the bag between the sealer's jaws.

- Press the jaws of the sealer together to create a seal. Hold for a few seconds until the seal is complete.

Look At Our Colored Mylar Bags Size Chart

Colored mylar bags come in a wide range of size options to accommodate various products and packaging needs. Here are some common mylar bags size charts available:

- Small Size: Small bags are typically used for packaging items such as samples, individual portions, or small products. These bags can range in size from 2 x 3 inches to 5 x 8 inches, providing enough space to hold smaller quantities.

- Medium Size: Medium-sized bags are versatile and suitable for a wide range of products. They can range from 6 x 9 inches to 8 x 12 inches, offering ample room for items like snacks, supplements, or personal care products.

- Large Size: Large bags are designed to accommodate bulkier or larger items. These bags typically range from 10 x 15 inches to 12 x 18 inches, making them suitable for packaging items such as bulk food items, clothing, or larger quantities of products.

- Custom Size: In addition to standard size options, custom bags can also customize to meet specific size requirements. This allows you to create bags that perfectly fit your unique product dimensions and ensure efficient use of space.

When choosing the size for your custom mylar bags with logo, consider the dimensions and quantity of the product you plan to package. It's important to select a size that provides enough space for the product to fit comfortably while considering any additional features such as resealable closures or hang holes.

Customizable size options give you the flexibility to find the perfect fit for your specific packaging needs.

Get Our Prototype Today For Your Food Mylar Bags

To obtain prototypes of our food mylar bags, we offer a seamless process that allows you to see and evaluate the quality and design of our products firsthand.

Here's how you can get your prototypes:

- Contact Us: Reach out to our customer support team via phone or email and express your interest in obtaining prototypes of our bags. Provide them with the details such as the specific size, style, and quantity of prototypes you require.

- Design Discussion: Our team will guide you through the design process, ensuring that we understand your requirements and preferences. We can discuss aspects such as the material, lamination options, printing methods, and any additional features you may need for your prototypes.

- Artwork Submission: If you have specific artwork or a logo that you want to incorporate into the prototypes, submit the digital files to our team. We accept various file formats, such as AI, PDF, or high-resolution JPEG, to ensure accurate reproduction of your design.

- Prototype Production: Once all the necessary details are confirmed, our production team will create the prototypes of your mylar packaging bags. We use state-of-the-art equipment and follow strict quality control measures to ensure that the prototypes are created to your specifications.

- Evaluation and Feedback: Once you receive the prototypes, take the time to evaluate them thoroughly. Assess the quality, design, and functionality of the bags. If any adjustments or modifications are needed, provide us with your feedback, and we will work closely with you to refine the prototypes to meet your expectations.

- Production Order: If you are satisfied with the prototypes and wish to proceed with a production order, our team will guide you through the order placement process, including discussing pricing, quantity, and lead times.

Obtaining prototypes allows you to assess the suitability of our mylar packaging bags for your specific packaging needs. And make any necessary adjustments before proceeding with a full production order. We value your satisfaction and are committed to delivering high-quality prototypes that align with your requirements. Contact us today to start the process and experience the excellence of our custom bags firsthand.

Look At Our Add-On Options For Mylar Gift Bags

To enhance the functionality and visual appeal of your mylar gift bags, we offer a variety of add-ons that can incorporate into the design. These add-ons provide additional features and customization options to meet your specific packaging needs.

Here are some popular add-ons available for mylar bag:

-

Resealable Zipper

A resealable zipper allows for easy opening and closing of the custom bag, ensuring the contents remain fresh and protected. This feature is particularly useful for products that require repeated access, such as snacks, coffee, or spices. The zipper is typically located at the top of the bag and can seal by pressing it shut. It is a popular add-on for food packaging, as it helps to maintain the freshness and quality of the product.

-

Hang Hole

A hang hole is a small punched-out opening located at the top of the bag, allowing it to be hung or displayed on hooks or pegs. This feature is beneficial for retail environments where products need to prominently showcase or organize.

By adding a hang hole to the bag, it becomes effortless to hang and display the packaged items, maximizing visibility and convenience.

It is commonly used for various products such as snacks, small accessories, or beauty products, allowing them to attractively present and organize on store shelves or displays. The hang-hole add-on offers retailers a practical and efficient way to exhibit their merchandise. Making it easier for customers to browse and select the desired items.

-

Tear Notch

A tear notch is a small pre-cut groove that facilitates the easy opening of the bag without the need for additional tools. It provides convenience for end-users, enabling them to access the contents quickly and efficiently. This feature is particularly beneficial for quick and hassle-free access to the contents of the bag.

Whether it's snacks, small products, or samples, the tear notch ensures a seamless opening experience, enhancing convenience for both retailers and end-users.

By eliminating the need for additional tools, the tear notch promotes user-friendly packaging and provides a convenient solution for customers on the go. It's a small yet impactful addition that adds value and enhances the overall user experience of custom bags.

-

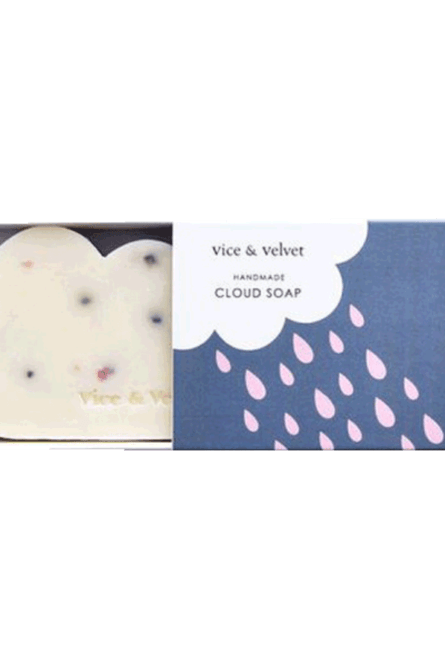

Mylar Bags With Window

A clear window is a transparent portion incorporated into the design of the mylar bags with window, allowing visibility of the product inside. This feature is ideal for products that rely on visual presentation, enabling customers to see the contents before making a purchase.

These add-ons can combine or use individually, depending on your specific requirements and product packaging goals. By incorporating these features into your bags, you can enhance functionality, and improve customer convenience. And create a visually appealing presentation that aligns with your brand image. Contact us to explore the add-on options available and discuss how they can tailor to meet your packaging needs.

Why Choose Us?

There are several compelling reasons why you should choose us as your provider of mylar packaging bags. Here are some key factors that set us apart:

- High-Quality Products: We are committed to delivering top-notch quality products. Our bags are prepared from premium materials, ensuring durability, strength, and excellent barrier properties to protect your products from moisture, oxygen, and other external factors.

- Customization Options: We offer a wide range of customization options to meet your specific packaging needs. From size, shape, and add-ons to custom printing and finishes, we can tailor the Mylar packaging bags to showcase your brand and product in the best possible way.

- Attention to Detail: We pay meticulous attention to every aspect of the manufacturing process. From design to production, our team ensures that every Mylar bag meets our high-quality standards, resulting in a finished product that exceeds your expectations.

- Competitive Pricing: We understand the importance of cost-effectiveness. That's why we strive to offer competitive pricing without compromising on quality. We aim to provide you with affordable solutions that meet your budgetary requirements.

- Timely Delivery: We value your time and understand the importance of timely deliveries. Our efficient production processes and logistics ensure that your orders are fulfilled promptly and reach you when you need them.

- Customer Satisfaction: Your satisfaction is our top priority. We pride ourselves on delivering excellent customer service and support throughout your entire experience with us. Our team is always ready to assist you.

What Sets Apart?

We invite you to contact us today and discover the exceptional quality and functionality of our mylar bags. Whether you need packaging solutions for food, cosmetics, pharmaceuticals, or any other industry, we are here to assist you.

Our enthusiastic team is ready to answer your inquiries, provide detailed information about our bags, and guide you through the ordering process. We understand the importance of finding the perfect packaging solution that meets your specific needs, and we are committed to delivering excellence at every step. To get started, simply reach out to us via phone or email.

Our knowledgeable representatives will be happy to assist you with any questions or concerns you may have. We can discuss your packaging requirements, including size options, material choices, printing methods, and any additional features you may need.

Don't hesitate any longer. Contact us today at Packaging Bee and let us provide you with the high-quality mylar packaging bags your products deserve.

We look forward to working with you and becoming your trusted packaging partner.