12

By: Monica Harper

The first patent registration of corrugated cardboard was made in England in 1856 by Edward Healy and Edward Allen. At that time corrugated cardboard was used for hatbands (!).

In 1874 Oliver Long took out a patent for single well-corrugated cardboard and one year later, in 1875, Henri Norris began the production of twin walls.

The first patent in the USA was taken out in 1889 and the very first cardboard box was manufactured in the USA in 1895.

What Does Corrugated Cardboard Consist of?

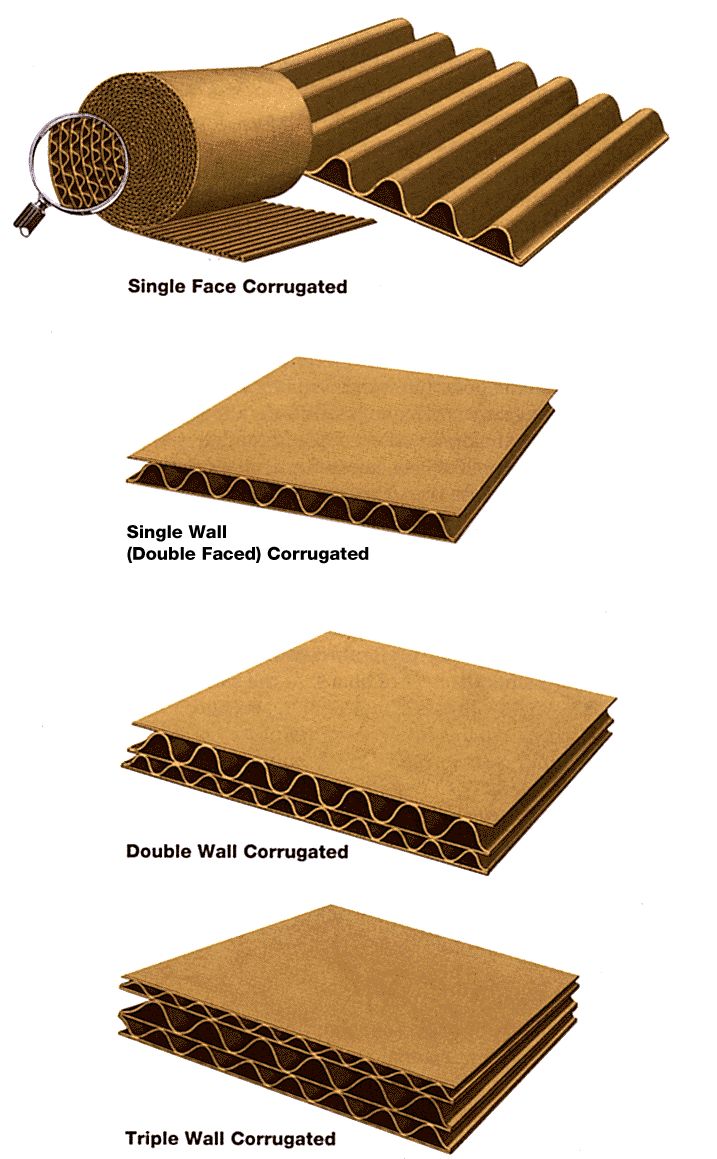

In short, corrugated cardboard consists of two layers of cardboard also called ‘liners’, and a corrugated central part called ‘fluting’ (deriving from the English word flute). The liner is manufactured from long fibers in order to make it strong and hard-wearing. The fluting is manufactured from short fibers in order to make it stiff and resistant to pressure.

This fantastic construction forms rows of stiff waves capable of sustaining large weights. Furthermore, the freely circulating air in the waves provides excellent protection against temperature fluctuations.

A Nature-Friendly Packaging

Corrugated cardboard is made of paper which again is made of new or recycled cellulose fibers. Up to 85% of all corrugated cardboard is recycled and is, therefore, a very environmentally acceptable packaging. A corrugated cardboard fiber may be recycled up to seven times before it loses its resilience.

Also, the glue is made of natural products of which maize is the most used raw material.

Many Types of Corrugated Cardboard

There are many types of corrugated cardboard – almost infinite combinations may be obtained when using different cardboard qualities and different wave heights. Qualities range from the very thin ones as those used for wrapping up presents, to Heavy Duty ones – of which a standard size cardboard box can contain about 3 tons, i.e. for instance a car!

Flexibility

Corrugated cardboard can be cut and folded in infinite sizes and shapes. It is also possible to print on corrugated cardboard and as a consequence, the packaging may serve both as a protection of goods as well as an advertisement display.

Strength

Strong quality corrugated cardboard boxes may easily be stacked on top of each other and are very pressure and push resistant both at the sides as well as at the top. Heavy Duty corrugated cardboard boxes may endure falling, vibrations, temperature fluctuations, moisture, and even being subjected to water at the bottom for many hours without damage to the cardboard.

The Production Process

The machine line for manufacturing corrugated cardboard is called ‘The Corrugator’ and it consists of as many as 12 different machines.